It is similar to fruit jelly but the slices or peels of the fruit remain suspended. Marmalades are typically made from citrus fruits such as oranges and lemons with pieces of the peel mixed in as a suspended material. As per FPO specifications, the content of fruit and soluble solids in the final product for jelly and marmalade should not be less than 45 and 64 percent (w/w), respectively.

Note

- The outer yellow peel of an orange, called flavedo, is an important source of vitamin C, polymethoxy flavones, and carotenoids.

- Inner white portion called albedo is a rich source of phenolics, flavanones, and antioxidants.

There are two types of marmalade (A) jelly marmalade (B) jam marmalade.

(A) Jelly Marmalades

Clear pectin extracts are used in Jelly Marmalades. Some of the best combinations for marmalade are:

- Sweet orange and Khatta or sour orange (C. aurantium) in the ratio of 2:1 by weight. Pieces of sweet orange peel are used.

- Orange and Khatta in the ratio of 2:1 by weight. Pieces of orange peel are used.

- Sweet orange and Galgal or lemon (C. limonia) in the ratio of 2:1 by weight. Pieces of orange peel are used.

(B) Jam Marmalades

Jam Marmalades are prepared in the same way as Jelly Marmalades, except that Jam Marmalades use the unclear extract, or it is not filtered and the whole pulp is used. Sugar is added in a ratio of 1:1. The pulp sugar mixture is cooked until the TSS content reaches 65%.

Recipe

Sweet Orange -1Kg

Lime – 0.5 kg

After Pectin Extraction

Pectin extract – 1 litre

Sugar – 750gm

Shredded Peel – 62gm

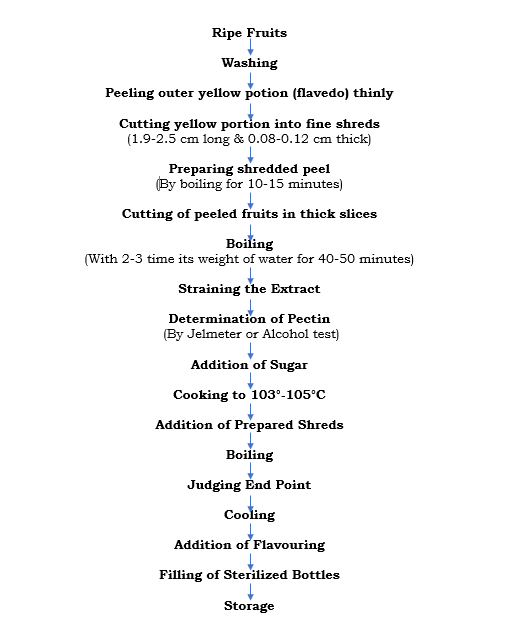

Flow sheet of Marmalades

Marmalade preparation process

Fruit preparation: The outer yellow flavedo part of the rind of citrus fruits contains coloring matter and volatile oils, while the inner white albedo part contains pectin. The yellow part of the peel is thinly peeled off the fruit with a stainless steel knife. The thin yellow peel is cut into fine pieces with a knife or using a shredding machine. The pieces are boiled and dried to remove the bitterness. Cut or crushed fruits are boiled slowly in water 2 or 3 times to extract the pectin. While it is being boiled, a teaspoon of clarified extract is taken from the pan and tested with alcohol or a gelmeter to determine its pectin content. The boiling process usually takes 45 to 60 minutes. After boiling, the extract is filtered through a muslin cloth. Pectin extracts can also be filtered with a filter press to obtain a clear extract.

Preparation of shredded peel: The peels (1.9-2.5 cm long and 0.8-0.12 cm thick) are cut. The pieces are boiled and softened before being added to the marmalade. If they are added directly to the sugar solution without softening and then boiled, they harden. Generally, three methods are used to soften shreds.

- The peel shred is boiled for 10-15 minutes by changing the water several times. In this process, the bitter principles present in the peel are also removed.

- The shreds are boiled in a 0.25% solution of sodium carbonate or 0.1% solution of ammonia.

- Or the pieces are autoclaved at 1160C to 1210C (70-105 kPa). The time required for the pieces to soften depends on their size and shape.

Cooking: The juice is boiled in a steam jacketed kettle or stainless steel vessel with the required amount of sugar. Boiling is continued and impurities that rise to the surface are removed. When the temperature of the boiling mixture reaches 1030C at sea level, ready shred pieces at the rate of 62 grams for every kilogram of the original extract are added to it. Boiling is continued until the gelling point is reached which is determined using the sheet test, drop test, or weight test.

Addition of flavour: Due to the volatile nature of the natural flavour during the cooking process, it is desirable to add artificial flavour to compensate for the loss. Typically, a small amount of orange oil is added to marmalades when filling in jars or cans as a flavour.

Packing: Marmalades after cooling are filled in jelly glasses or glass jars, which can be airtight closed or packed in cans that are hermetically sealed. The marmalade is allowed to set overnight in jelly glasses and when cooled, a thin layer of melted paraffin wax is poured over the top. Then packaged in A21/2 sized cans, then stored in a cool dry place with the lids upside down to sterilize.